KTR-07

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Detail

-

Seat performance characteristics description

Seat model: KTR-07

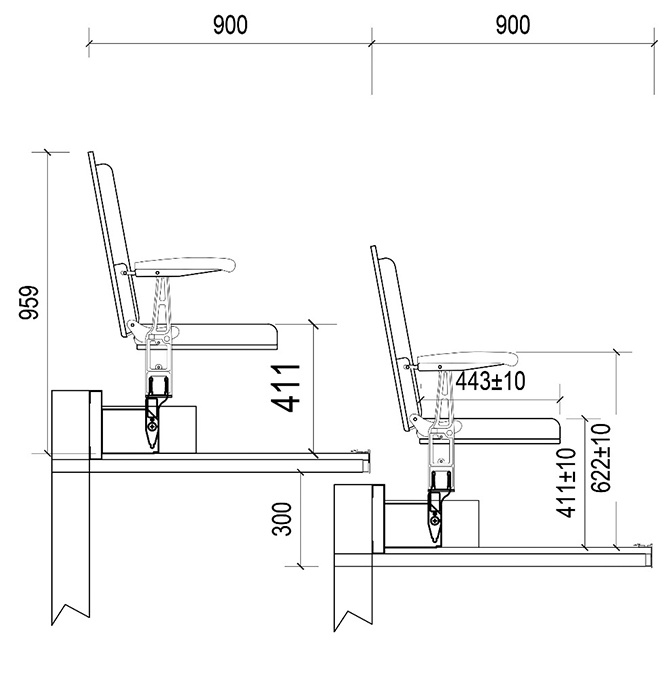

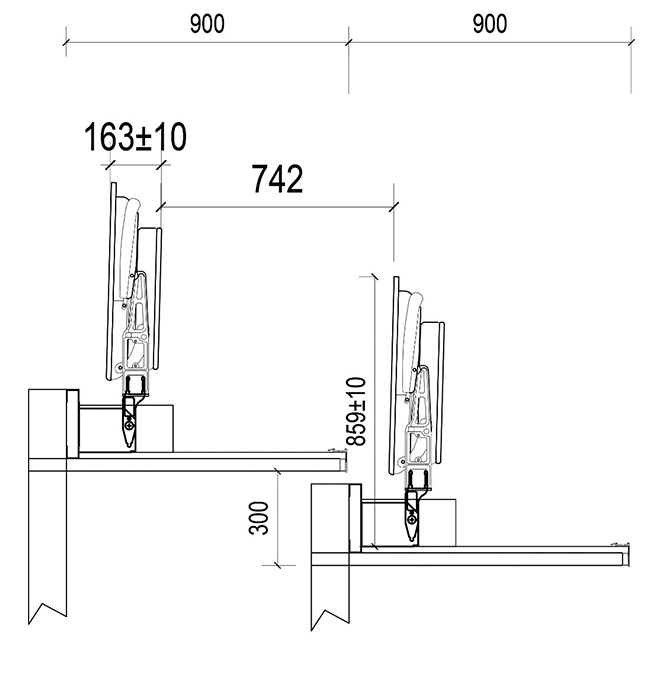

Seat distance 520MM row distance 900MM.

1. The surface modeling of the seat is designed according to the principle of body function. The back of the chair is in maximum contact with the human body, and the curvature of the backrest and cushion is fully in line with the physiological curve of the human body, increasing the force point. Sit comfortable, beautiful and generous. The indicators of the seats meet the technical standards of QB/T2602-2013 "Film and Theater Public Seat Industry Standard".

2, the seat uses polyurethane foam high resilience sponge, according to different requirements, the back, the cushion using different density sponge, in order to maximize the comfort. The sponge is added with imported flame retardants, and the fire rating of the sponge meets the B1 level standard of GB 8624-2012 "Combustion Performance Classification of Building Materials and Products". The release of harmful substances is very low, and the release of formaldehyde, toluene and TVOC meets the standards of GB/T 1883-2002 "Indoor Air Quality Standard".

3, the seat fabric selection of flame retardant knitted fabric, there are a variety of colors for users to choose, the fabric is flame retardant fabric, its flame retardant performance to GB/T 17591-2006(flame retardant fabric) decorative fabric B1 standard.

The physical properties have reached the standard of GB 18401-2010 "National Basic Safety Technical Specification for Textile Products" and GB/T 19817-2005 "First-class standard for textile decoration fabrics".

4, the seat set solid wood armrest, streamline design, coated with polyester polishing paint, beautiful shape, comfortable touch.

5, the seat and the back of the chair set decorative board, decorative board by wooden multi-layer board high frequency pressing molding, the skin is beech bark, coated with high frequency polyester polishing paint, beautiful and elegant. Decorative board long-term use does not crack and has good moisture-proof function.

6, the seat adopts the back seat integrated connection device, when using, you only need to gently press the seat with your hand, and the seat automatically rebounds when not in use, and no noise.

6, all metal surface after sandblasting rust treatment, and then electrostatic spraying. Plastic powder and metal surface adhesion is very strong, corrosion resistance and scratch resistance is better than the national standard.

7, all standard parts (bolts, nuts) are selected high-quality national standard products.

Dimension drawing

Case

Detail drawing

KTR-07

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!