HYC19-04

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Detail

-

Technical specification

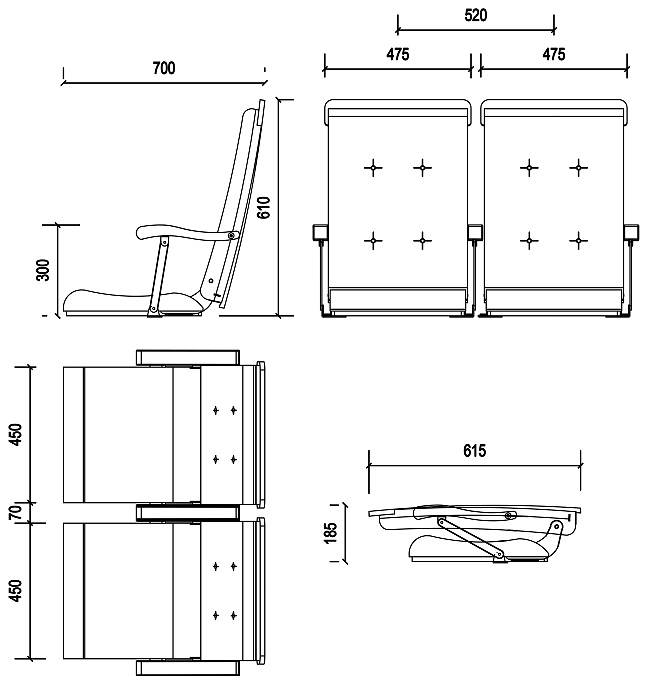

Height of chair 610mm±10 Seat center distance 580mm±10 Height of seat 400mm±10 Seat depth 430mm±10 1. The seat is designed and manufactured according to the principle of body shape engineering, and the seat feels comfortable. Seat cushion, backrest and human body contact part adopts soft bag design, the back of the seat is provided with wooden decorative board. The seat has unique shape, beautiful appearance, comfortable sitting, high strength and impact resistance. The connection of each component of the seat is reasonable and reliable, and the bearing capacity is strong.

2. The seats are equipped with solid wood armrests, coated with polyester polishing paint, streamlined design, beautiful shape and comfortable touch. Armrests automatically fold with the seat, simple and practical. Armrests automatically fold with the seat, simple and practical. Decorative board is arranged on the back of the chair seat. The decorative board is made of wooden multi-layer board, the skin is beech bark, and the high-frequency polyester polishing paint is applied. The shape is beautiful and elegant. The decorative board does not crack for a long time and has good moisture-proof and dust-proof functions.

The adhesion and impact resistance of the paint film of the wooden seat are in accordance with the grid test of GB/T 9286-1998 color paint and varnish film, GB/T 17657-2013 test method for physical and chemical properties of wood-based panels and decorative wood-based panels.

3, backrest, cushion sponge for high rebound shape sea, the use of automatic CNC foaming unit production, all sponges with high consistency, long-term use will not deform, sponge density of 30-40 kg/m³. The base material is thermoformed plywood, the backplane thickness is δ15, and the formaldehyde emission meets the E1 standard.

4, fabric selection of brand fabric, high wear resistance, strong penetration, sound absorption effect is good. The relevant indicators of fabrics reach and exceed GB/T17591-2006, GB 18401-2010, GB/T 19817-2005, GB/T 5713-2013, GB/T3922-2013, GB/T3920-2008, GB/T 3923.1-2013 , GB/T 3917.3-2009, GB/T7573-2009, GB/T2912.1-2009, GB/T 17592-2011, GB/T 21196.2-2007, GB/T 4802.2-2008, GB/T2910.24-2009 Standard requirements:

Flame retardant performance: B1 level.

5, the back of the chair is set up decorative board, decorative board is made of wooden multi-layer board high frequency pressing molding, the skin is beech bark, coated with high frequency polyester polishing paint, beautiful and elegant. The decorative board does not crack for a long time and has good moisture-proof and dust-proof functions.

6, the seat through the Tsinghua University built Environment monitoring Center reverberation room monitoring, the seat in accordance with GB/T 20247-2006/ISO 354:2003 "Acoustic reverberation room sound absorption measurement" in the technical standards.

7, all metal surfaces are sandblasting rust removal treatment, and then electrostatic spraying, sandblasting rust removal effect is good, plastic powder and metal surface adhesion. The adhesion of the paint film must meet the GB/T 9286-1998 paint film grid test level 1 standard. Alkaline resistance, oil resistance, medium resistance must meet the technical requirements of GB 9274-1988 resistance to liquid media.

8. Install seat numbers for each seat.

Dimension drawing

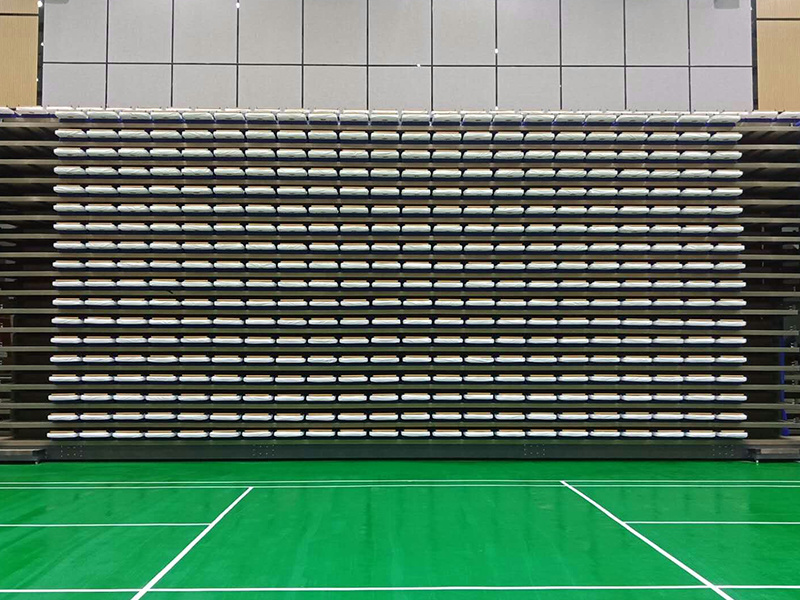

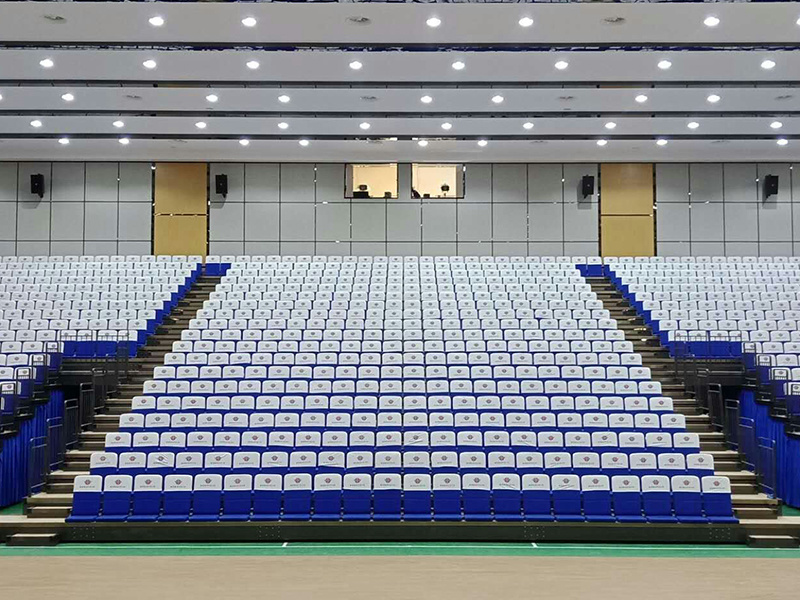

Case

Detail drawing

HYC19-04

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products