HYC19-07

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Detail

-

Specification of performance characteristics

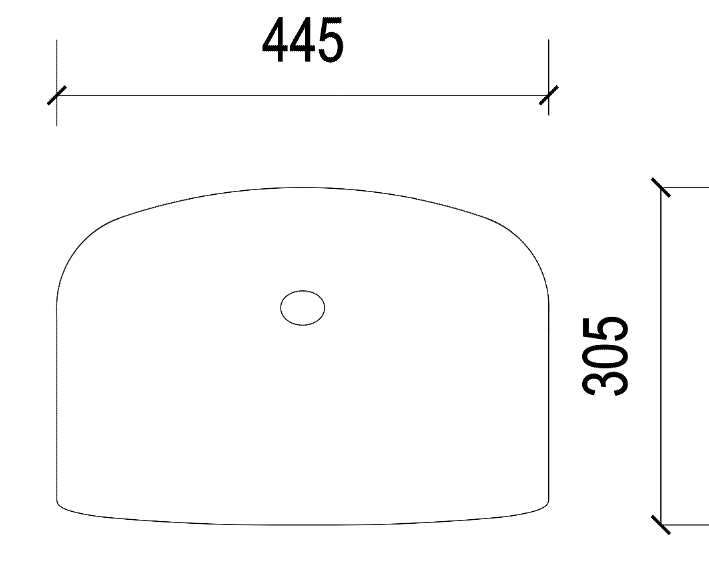

Seat model: HYC-19-07

Seat size: Seat width 445mm, seat depth 305mm, seat height 430mm.

1 The seat is designed and made according to the principle of ergonomics, comfortable and beautiful, and the seat meets the technical standards of QB/T2601-2013 (industry standard for public seats in sports venues).

2, the seat is made of Sinopec high-density polyethylene as raw material, adding anti-ultraviolet additives, using hollow blow molding process, high strength, impact resistance, simple installation. After xenon lamp aging test for 4000 hours, the seat has no powder, crack, fade and other phenomena.

3, the seat has good weather resistance, tested by professional testing institutions, the seat is stable in the environment of 60 degrees below zero to 80 degrees, no fading, no odor, no deformation.

4, the seat materials are up to green environmental protection standards, and harmless to the human body. The release limit of harmful substances in the seat is in line with GB 28481-2012 "Limit of harmful substances in plastic furniture" standard.

5, metal fixed parts after sandblasting rust treatment, and then electrostatic spraying. Plastic powder and metal surface adhesion is very strong. The adhesion of paint film reached GB/T 9286-1998 paint film grade 1 standard. Alkaline resistance, oil resistance and medium resistance meet the technical requirements of GB 9274-1988 (determination of liquid medium resistance).

6, screw selection of high quality national standard products.

7, the product has red, yellow, blue, green and other colors for customers to choose.

Bed frame structure description

The movable stand is mainly composed of guardrail, pedal, stand controller, bottom front beam, anti-slip strip, corner guard, aluminum alloy decorative strip, load-bearing beam and support system. Active stand light weight, large load, bed load 500KG/㎡, guardrail load 100KG/M.

1. Support system

The stand support system is welded with 40mm*120mm*2.5mm steel pipe, which has reasonable structure and strong bearing capacity. Under the support system is the walking wheel frame, the outline size is 40mm*120mm, the support wheel is installed under the support wheel frame, the diameter is 100mm, the width is 30mm. The column of the support system is a rectangular tube of 40mm*120mm*2.5mm, the upper part of the column is connected with the bearing beam, and the guiding mechanism is arranged below the column for guiding the walking wheel frame of the next layer, ensuring that the stand always moves in a straight line. A diagonal brace is arranged between the column and the rear beam of the support structure to ensure that the column and the rear beam are always in a vertical state, ensuring the stability and safety of the support system, and there will be no swaying from side to side.

2. Front and rear bearing beams.

The front and rear of each bed frame are provided with load-bearing beams, the rear load-bearing beams are made of cold-rolled steel plate bent, the overall size is 40mm*220mm*2.5mm, the front beams are 20mm*40mm*2.0mm rectangular tubes, the front and back beams are closely connected with the supporting columns, forming a whole, the structure design is reasonable, the bearing capacity is strong, and the deformation is not easy.

3. Pedal system

The pedal system is mainly composed of support bracket, wooden board, surface layer, aluminum alloy decorative strip, rubber anti-slip strip and plastic corner protection. The support bracket is welded with 40MM*40MM*1.5MM square steel pipe and evenly arranged between the front beam and the back beam. Laminated plywood with a thickness of 18mm is laid on the top of the support bracket. The plywood is fixed on the support bracket by screws. The countertop is flat and not easy to be deformed. The surface of the wooden board is laid with gray PVC floor glue with a thickness of 2MM. The surface is flat, non-slip and wrinkle-free, which is easy to clean.

Aluminum alloy decorative strips are installed on the front and both sides of each layer of pedals, the overall size is 60MM*72MM*1.5MM, and rubber anti-slip strips are inlaid above the aluminum alloy, and plastic corner guards are installed at the aluminum alloy corner. Based on the above design, the pedal looks beautiful and can effectively prevent the audience from slipping and scratching.

Step: A box-type step is set at the channel of each layer above the stand, the height of which is half of the height of the storey. The step skeleton is bent by cold-rolled steel plate with a thickness of 1.5MM. The top of the skeleton is laid with wooden boards, floor glue, aluminum alloy and corner protection.

4. Safety fence

On both sides of the stand bed frame, the rear side (no rear guardrail when leaning against the wall) is installed with safety guardrail, and the height and spacing of the guardrail are designed and manufactured according to relevant national standards. The guardrail adopts laminated design, which can automatically expand with the grandstand when it expands. The outer frame of the guardrail is made of 20MM*40MM*1.5MM steel pipe bent, and the guardrail and the stand bed frame are fixed and connected by bolts, which has strong bearing capacity and is not easy to deformation.

5. Drive system

The drive system is mainly composed of drive wheel, transmission shaft, sprocket, deceleration motor, etc.

The driving motor is installed at the bottom of the first row of the platform, using the products of well-known domestic manufacturers, working voltage voltage 380V/220V, frequency 50HZ, power 0.37KW-1.5KW, motor noise is less than 50DB. The output torque of the motor is transmitted to the driving wheel through the chain, sprocket, transmission shaft, etc. The inner core of the driving wheel is cast iron, and the outer layer is wrapped in rubber, which increases the friction while protecting the ground from damage to the maximum extent. Each group of driving mechanism is equipped with 4 driving wheels to ensure smooth operation of the stand and no deviation phenomenon.

6. Electrical system

The electrical system of the active stand adopts three-phase 380V or single-phase 220V power supply, which is equipped with overload protection and leakage protection devices, and can quickly cut off the main power supply when there is leakage or overload, so as to avoid accidents. The control part of the movable stand adopts 24V low-voltage control circuit, and the first row vertical plate is installed with a handle socket. When operating the stand, you only need to insert the handle plug into the socket to expand, withdraw and suspend the operation of the stand. The movable stand is equipped with a limit switch, which can automatically stop running when it is deployed or withdrawn in place.

7. Side decoration

In order to prevent spectators from entering the inside of the stand, both sides of the stand are covered by flannel curtain, and the stand bed frame is equipped with side curtain slipway, which can automatically close with the stand when the stand is extended. The side curtain has red, gray, black for users to choose, the side curtain is not only beautiful and generous, but also has a sound absorption effect, which can improve the reverberation effect of indoor sound.

Dimension drawing

Case

Detail drawing

HYC19-07

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!