SYEC00003 Qifan-58 Seat distance - 1.2m row distance

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Detail

-

The seat is designed and developed by the principle of ergonomics, and the seat feels comfortable. The seat cushion is made of lining board, foam and leather bag. The backing board and the seat lining board are customized with high-quality environmental protection plates. The internal wood structure is made of dried and planed larch wood, which does not deform or crack. The internal filling material of the soft core is polyurethane high resilience sponge. The seat base is welded with high-quality steel and processed by sandblasting, rust removal and electrostatic spraying to ensure that the seat is firm and solid.

Crafts & technique features

Surface material Black microfiber skin for human contact, leather for non-human contact backrest The skeleton is made of high-quality wood for custom processing, after multiple processes, drying, anti-mold treatment, insecticide, disinfection, etc., the moisture content and other indicators reach the national standard

It is connected with rubber stretch tape to ensure more comfortable leaning

The interior is filled with polyurethane high resilience setting sponge and part of high-quality space cottonCushion seat It is welded with high-quality steel and processed by sandblasting, rust removal and electrostatic spraying. The S-type spring is evenly distributed and connected to ensure comfortable resilience.

The filling material is polyurethane high resilience setting sponge

handrail The skeleton is custom finished with high quality wood

This type of seat can be combined with a shared armrest

Chassis structure Made of high quality steel welded through sandblasting, rust removal, electrostatic spray treatment

The whole sofa is on the iron chassis frame to extend the service life of the whole sofa

Trial location: Cinema

Telescopic mode: fully fixed

Fabric selection: leather (first layer of cowhide), imitation leather (leather), microfiber leather

Optional accessory: airbrushed embroidery LOGO

Photo [Tip] The color of the picture has been as close to the real thing as possible, but because of the different factors such as shooting light and pixel and display resolution, the overall effect will have a certain color difference. See the attached photo for details

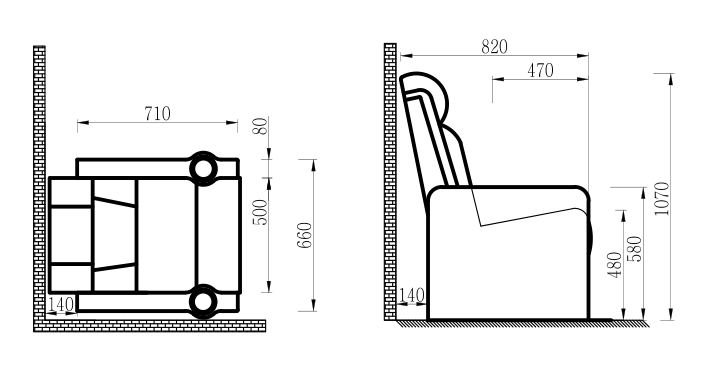

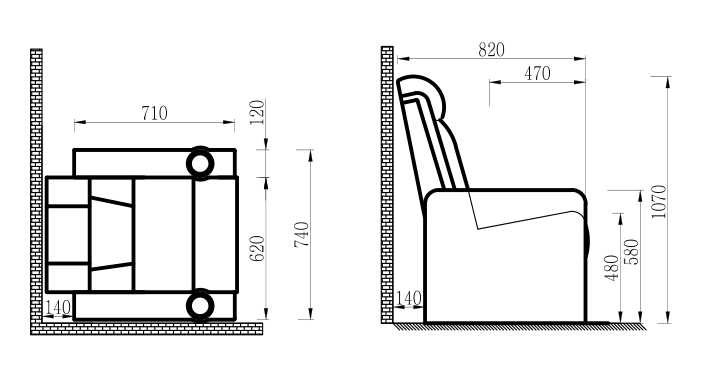

Wire frame size reference (for reference only) : See the attached table for details

Detailed introduction:

Designed and developed according to the principle of human function, the seat feels more comfortable, according to the international standard requirements for research and development design, to ensure comfort, high-end enjoyment.

Armrest box after multi-process treatment, drying, anti-mold treatment, insecticide, disinfection, moisture content and other indicators to meet the national standard, attached 10mm thick high-strength qualitative sponge, surface fabric style and color can be customized to meet customer requirements, armrest interior inlaid for brushed silver cup holder.

The cushion frame is welded with high-quality steel. After sandblasting, rust removal and electrostatic spraying, the filling material inside the cushion is polyurethane high resilience shaping sponge, and the S-type spring and rubber elastic pull belt are uniformly connected to ensure the comfort and resilience of the cushion.

The backrest skeleton is made of high-quality wood for custom processing, after multiple processes, drying, anti-mold treatment, insecticide, disinfection, etc., the moisture content and other indicators meet the national standard. The internal filling is polyurethane high resilience shaping sponge, and the rubber elastic pull belt is connected to ensure more comfortable leaning.

This type of seat can be combined with a shared armrest.

Special Remarks: The product can be customized according to the actual situation of the customer's theater venue (in general, only the width of the armrest is changed, and the width of the seat cushion is unchanged).Dimension drawing

Case

SYEC00003 Qifan-58 Seat distance - 1.2m row distance

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products