Vibrate seat Millennium

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Detail

-

Seat structure, performance and material description

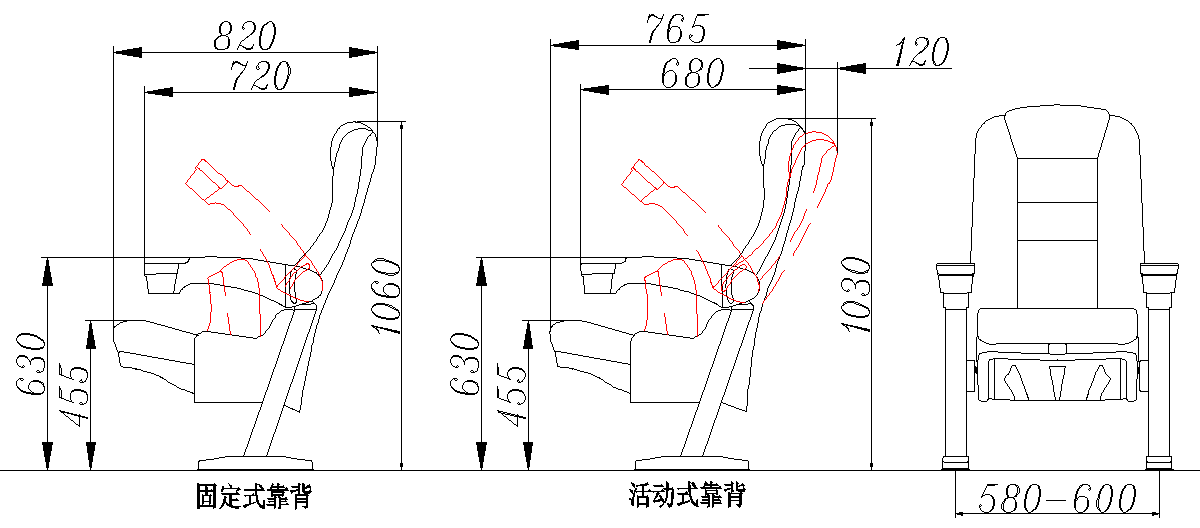

Note: ① The size unit of the appearance of the figure is mm, and the individual data of the actual product may have an error of about ±10mm.

② The fixed backrest in the figure is a large tilt, and the difference between the top of the backrest and the top of the backrest is about 50mm; The movable backrest degree is the middle degree, and the difference between the top of the two adjacent backrest degrees is about 40mm.

Main technical parameters

Height of chair 103-106cm Center distance of chairs 58-60cm Height of seat 45.5cm The minimum row distance is recommended 105or110cm Handrail height 63cm Minimum length 68cm Maximum length 88.5cm Foam density 45kg/m3 Seat depth 45-467cm Maximum load-bearing capacity of the seat 150kg Back across 50cm Number of seat reversals 20万次 Structural composition

The seat is mainly composed of iron armrests, plastic cup holders, backrest, seat cushion and connecting flipping mechanism.

Performance and characteristics

1. The backing board is made of wood multilayer plywood, durable, no deformation, no cracking; The soft core of the back is made of high rebound cold foam polyurethane mold with a density of 45kg/m³; The back shell and seat shell are made of modified PP engineering polypropylene molding, with corrosion resistance, aging resistance, easy to clean and other characteristics.

2, the soft core of the seat is molded with high rebound cold foam polyurethane and steel structure skeleton, built-in "S" shaped spring, foam density is 45kg/m3, and the seat can be installed according to the seat number.

3, the back of the chair can be made of fixed and movable two, fixed backrest connection structure is 4mm thick high-strength steel sheet stamping, durable without deformation; The movable spring of the movable backrest is a 3mm thick spring plate, and the limiting structural part is a 5mm thick high-strength steel plate. The life of the spring plate can reach 200,000 times.

4, fixed backrest degree provides two adjustable, movable backrest degree provides three adjustable.

5. The reversing mode of the seat cushion adopts the gravity rebound device, the counterweight and the seat skeleton are welded into one body, and there is no risk of falling off. The seat cushion is returned accurately, smoothly and with minimal noise.

6. The seat armrest is equipped with a cup holder, which is molded with high-strength ABS engineering plastic. The outer diameter of the cup holder is 110mm. The upper cover and bottom plate of the cup holder are wrapped with cloth. The side armrests are equipped with side panels, and are covered with cloth, which is beautiful and generous. The anchor bolt is hidden, and the plastic anchor cap is sealed after fixing, reducing dust accumulation, convenient cleaning, stable and beautiful.

7, the iron handrail is made of 1.7mm thick steel pipe dioxy welding, the upward head is 7mm thick steel plate stamping, the lower foot is stamped by 2mm thick steel plate mold, and the fixed hole distance of the foot is 242mm.

8, all metal surfaces of the seat are sandblasted rust removal, and then electrostatic powder spraying coating rust prevention treatment.

9. The seat automatic rebound axle is a high-strength nylon injection molded part.

10, the seat fabric a variety of colors, varieties for customers to choose and can do flame retardant treatment, its combustion performance can reach B1 flame retardant standards.

11. All connecting fasteners (bolts, nuts, self-tapping nails, rivets, etc.) are selected as national standard parts, and the surface is galvanized or boiled black anti-rust treatment.

Function introduction and main equipment

Serial number name Feature Graphical representation 1 Low frequency vibration ● Located inside the backrest and cushion (some theaters only add vibration to the cushion);

● Vibration mode is low frequency vibrator;

● Vibration frequency 20-200HZ;

● The connection mode with the seat is curved spring connection, which makes the vibration more real;

● Simulate explosions, collisions, etc.;

● The seat follows the sound effect in the film to produce the corresponding vibration effect, which is transmitted to the human body through the seat and the back of the chair, so that people can move together with the film.

● With meticulous vibration, you can get in close contact with the film, convert the audio signal into a vibration signal and transmit it to the human body through the seat, and feel the shock of the film with the body.

2 Low frequency vibrator ● This device can be installed in the seat cushion part, can produce strong low-frequency vibration with the heavy bass effect of the film, so that people can feel the earthquake, tsunami, train collision, explosion and other strong vibration effect in the film picture.

● The device is improved on the basis of existing vibrators in the market, increasing the original shock force, installed in the seat to make the shock force distribution more uniform, current and voltage are safe voltage, the surface of the mesh cover heat dissipation performance is very strong, and has overheating protection function, power consumption is also very small.

3 Ring transformer ● Compared with ordinary transformers, the power is significantly increased and the voltage is stable.

● Very low AC noise, suitable for the audio industry.

4 Sound-vibration controller ● The machine room controller is connected to the bass channel of the cinema amplifier, and the sound of the bass channel is decoded and sent to the low-frequency vibration plate on each seat, and the low-frequency vibration plate drives the low-frequency vibrator to vibrate and realize the individual vibration of each seat.

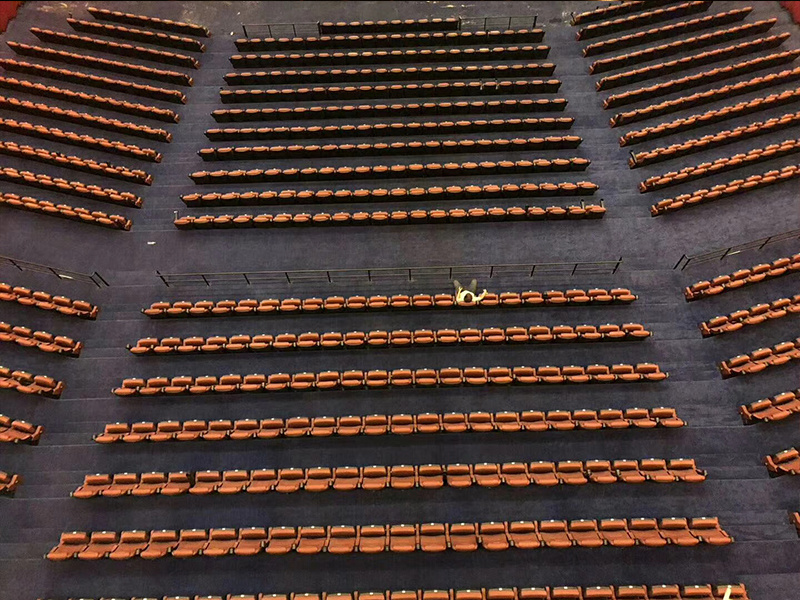

Case

Detail drawing

Vibrate seat Millennium

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!